AuraTec

AURATEC is a smart and dependable inspection system that is equipped with a visible laser beam and line scan camera providing unmatched accuracy in the industry. The true advantage lies in the tolerance of the container positioning. Providing consistent inspection under any production line condition, results are accurate with no false rejects.

image-3ci

FILTEC3CI

Case sealing machines are not capable of detecting broken, misplaced, or proper container placement in the case. The

FILTEC 3CI is a full case inspection system for closed or open cases with glass, PET, or can containers. Incorporating a case inspection system on your production line will eliminate downtime, product loss, and quality and customer satisfaction issues.

Filtec-3-Cutout-Revised-Medium-e1477600449706

Filtec3XR and 3G

Compact. Efficient. The most reliable, high-speed fill level inspection system worldwide for decades. Available in both X-Ray and Gamma configurations, the FILTEC 3-XR and 3-G is one of the most used fill level inspection systems in the beverage industry.

INTELLECT+

Intellect+

INTELLECT+ is an advanced modular system that provides:

- Upgradeability for customers with existing FILTEC inspection systems, eliminating obsolescence concerns and enabling expansion capabilities

- Flexibility and expandability by supporting all FILTEC inspection systems, whether at initial installation or by incorporating additional inspections sensors at a later date thus saving cost, production line real estate, and inventory

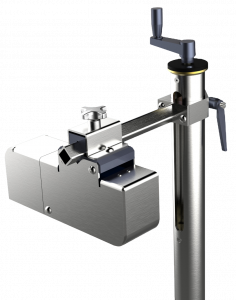

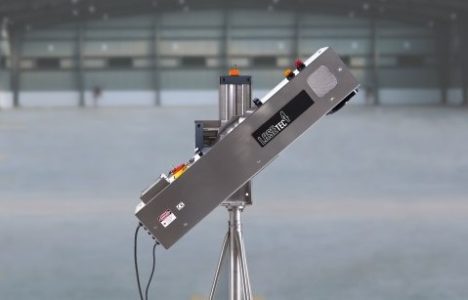

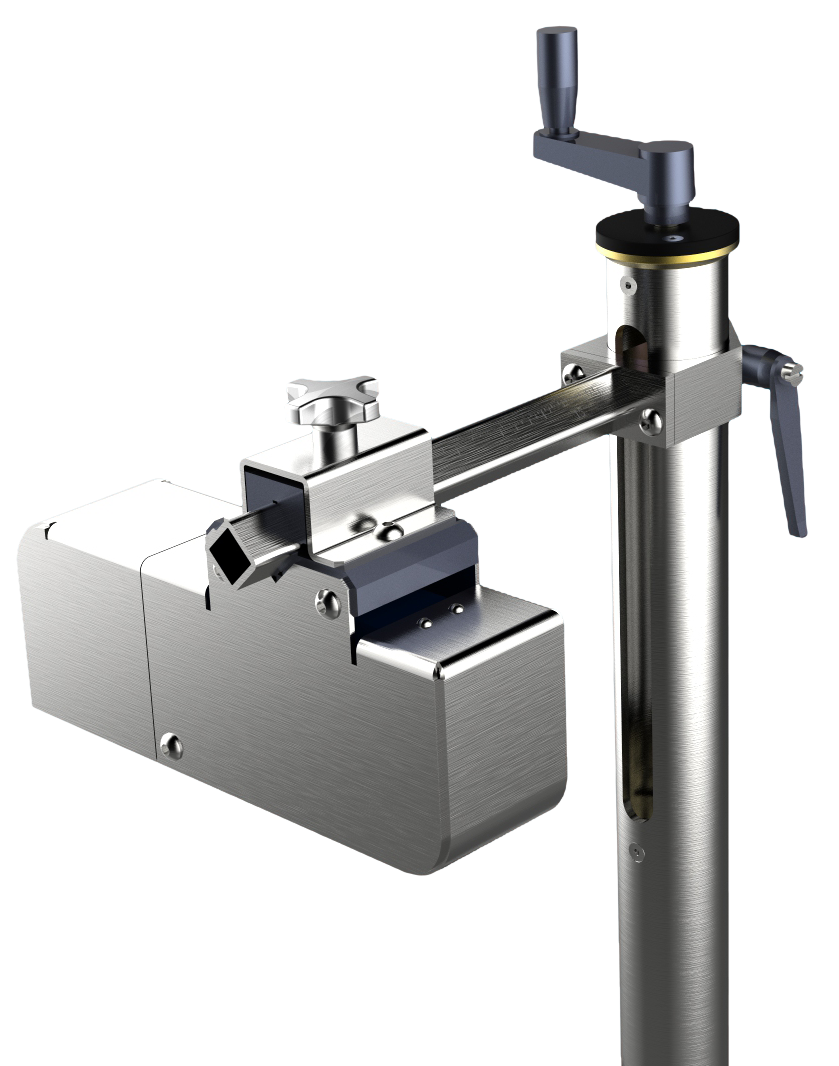

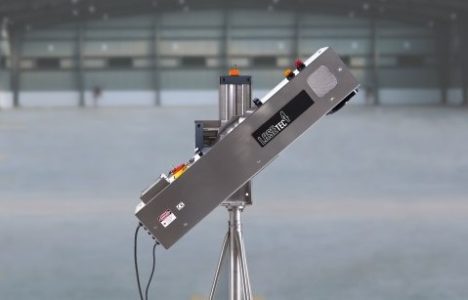

Lasetec

LaseTec4

LaseTec4 high-speed laser coding for customers who prioritize quality, accuracy, flexibility, and durability.

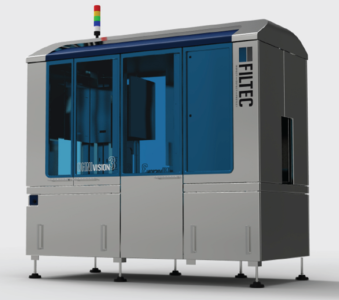

Omni rendering stand alone

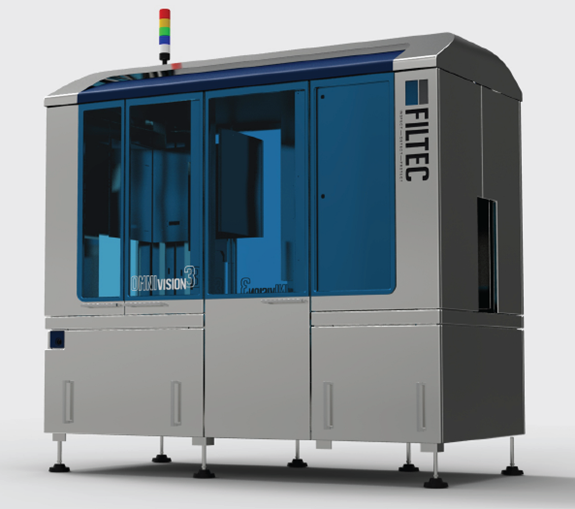

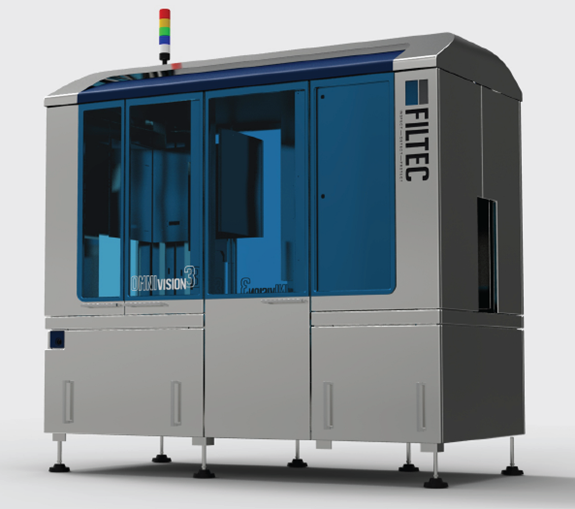

OmniVision3

OMNIvision3 is an all surface Empty Bottle and PET Inspection System that detects foreign objects and flaws in the base, sidewall, finish, and threads of empty transparent containers. OMNIvision3 has the fastest image processing technology in the market.

Spectrovision

SpectrovisionECI

The

Spectrovision ECI unit inspects the inner sidewall, base, and rim of cans for contaminates, damages and foreign objects. Production faults and transport damages are effectively rejected before reaching the filler, preventing loss of product and would-be faulty seams.

image-vision

Vision

INTELLECT+ VISION is a highly advanced, modular vision system to fulfill a wide variety of packaging inspection requirements including fill level, closure, and label inspection. VISION's inspection capabilities allow for a wide range of configurations to meet the changing needs of the modern packaging line.