FILTEC 3-XR and FILTEC 3-G

Compact. Efficient. The most reliable, high-speed fill level inspection system worldwide for decades. Available in both X-Ray and Gamma configurations, the FILTEC 3-XR and 3-G is one of the most used fill level inspection systems in the beverage industry.

Features

- Manual or motorized height adjustment for head trigger—precise, reliable, and convenient action

- Touchpad interface and integrated power switch

- Smaller footprint for easy installation

- Can 2,400 CPM and bottle 1,400 PM

- X-ray or gamma option

- Stainless steel construction

- NEMA 4X / IP65

Benefits

- Continuous monitoring and statistical analysis of line operations

- Sampling of filler valves and closer/capper heads at high production speeds

- Isolates and evaluates performance of individual filler valves and closer/capper heads

- Flexible inspection options

- Eliminate false rejects due to foam presence and filler malfunctioning

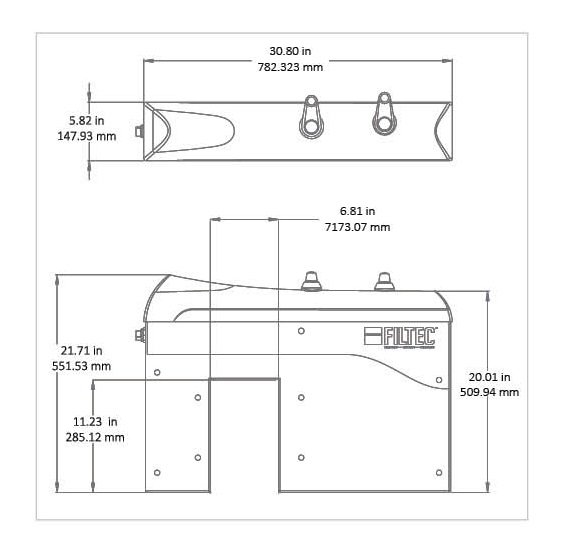

Specifications

- Air Consumption 0.5 scfm

- Electrical Requirements 115 VAC 50, 60 Hz 2amp 230 VAC 50, 60 Hz 1 amp

- Operating Temperature 0°C to 45°C

- Operating Speed Up to 2400 CPM (cans) Up to 1400 CPM (bottles)

- Rejectors Proline, Servotec II, Slat Rejector

- Display Languages As Required

- Networking Interface MODBUS Serial, MODBUS TCP/IP, Weihnstephan/OMAC

- Environmental Standards NEMA 4X / IP65

- Materials Stainless Steel Construction