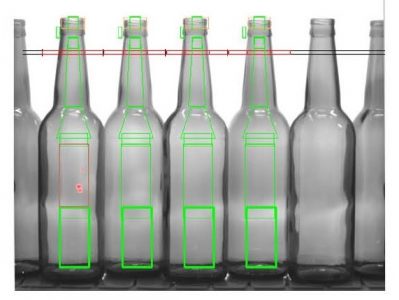

- High-resolution CCD camera

- Adjustable filters for embossing and varying bottle designs

- Detection of flaws both inside and outside of the container

- Up to 6 different inspection zones

- Cellophane / bright field detection

Is the container clean? Does the container have the right fill level? Is the label in the correct location? With FILTEC inspection systems, you don’t need to worry. Our systems use multiple algorithms to monitor your containers and remove containers that do not meet your quality standards.

Filter inspections by category

The base of a bottle receives the most amount of wear during the container’s life, and easily sustains scuffing or chips. A thorough inspection of both the inside and outside of an empty container’s base prevents flawed packaging and contaminated product from reaching the market.

OmniVision3 all surface bottle inspection system.

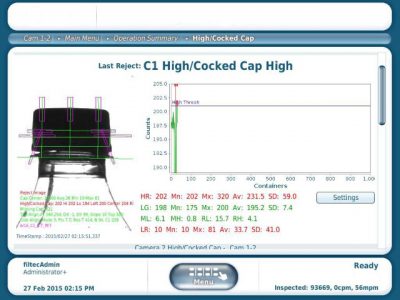

Learn MoreIncorrectly applied caps and broken tamper bands can cause pressure to leak from the container and can cause the spoilage of certain products.

FILTEC equipment can also inspect for cap color and artwork ensuring that branding remains consistent throughout the production process.

INTELLECT+ integrated modular future-proof package inspection interface.

Learn MoreFILTEC 3-XR and 3-G x-ray, optical, and gamma fill level inspection system

Learn MoreAuraTec pressure detection with multi-point laser scanning technology.

Learn MoreVision modular vision system inspects fill level, closure, and labels.

Learn MoreLINE ANALYTICS AND OPTIMIZATION

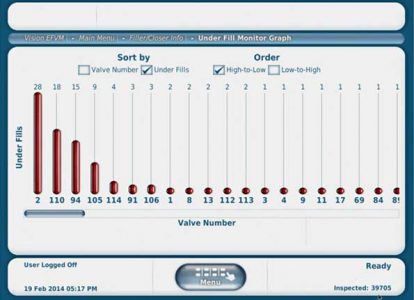

Closely monitoring filler and capper performance keeps high-speed line operations smooth. FILTEC systems can identify underperforming or broken valves and capper heads within seconds. Immediate warnings prevent wasted product, container damages, and line failures. Analytics provide detailed foundations for line planning and optimization.

Incorrect fill level and faulty seaming can be a symptom of a poorly tuned filler valve or a failing seamer. We can help you track these flaws back to the individual filler valves and seamer heads so you can keep your lines fine-tuned for maximum efficiency and minimal waste of product.

LaseTec4 high-speed laser coding, code verification, and code detection equipment.

Learn MoreINTELLECT+ integrated modular future-proof package inspection interface.

Learn MoreFILTEC 3-XR and 3-G x-ray, optical, and gamma fill level inspection system

Learn MoreAuraTec pressure detection with multi-point laser scanning technology.

Learn MoreVision modular vision system inspects fill level, closure, and labels.

Learn MoreFinely-tuned fill level inspection on can lines is a complex marriage of speed and accuracy. FILTEC has been performing this rapid-fire dance for decades, ensuring that no empty or partially-filled cans reach the market and preserving consumer trust through countless millions of flawless containers. We offer options for both gamma and x-ray source systems. Please contact your local FILTEC representative for help determining which works best for your market.

LaseTec4 high-speed laser coding, code verification, and code detection equipment.

Learn MoreINTELLECT+ integrated modular future-proof package inspection interface.

Learn MoreFILTEC 3-XR and 3-G x-ray, optical, and gamma fill level inspection system

Learn MoreAuraTec pressure detection with multi-point laser scanning technology.

Learn MoreVision modular vision system inspects fill level, closure, and labels.

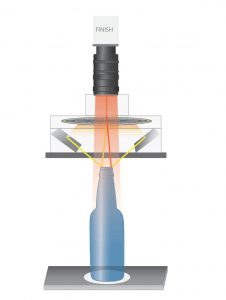

Learn MoreThe finish of a bottle or container is the very top surface where the cap is applied. For returnable glass especially, this surface can easily chip while in the market or during the washing process and cause problems with proper capping and sealing. If a chipped finish does make its way back out into the market, sharp edges can harm the end consumer.

OmniVision3 all surface bottle inspection system.

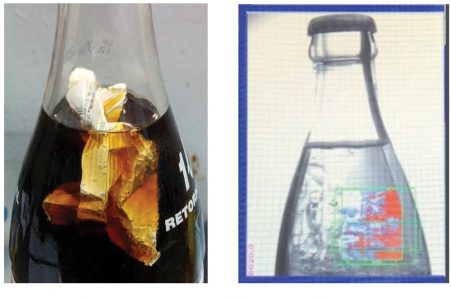

Learn MoreLarge objects may remain stuck in returnable containers after the washing process and float hidden in the necks of filled containers. In dark liquids, clear plastics and bits of paper may be difficult or impossible to see, but with powerful strobes FILTEC equipment can pick them out easily.

INTELLECT+ integrated modular future-proof package inspection interface.

Learn MoreFILTEC 3-XR and 3-G x-ray, optical, and gamma fill level inspection system

Learn MoreAuraTec pressure detection with multi-point laser scanning technology.

Learn MoreVision modular vision system inspects fill level, closure, and labels.

Learn MoreThe bottle’s inner sidewall is made up of all the inside surfaces from the base up through the neck. Damages in these surfaces can be difficult to see with the human eye, but can easily grow mold internally or shed glass into the product after it has been filled.

OmniVision3 all surface bottle inspection system.

Learn MoreFILTEC also provides high speed laser coding, code verification, and code detection equipment for cans. Our LASEtec 4 is a premier coder, built for high speed production and can reach speeds of 2,400 cpm with perfect accuracy.

LaseTec4 high-speed laser coding, code verification, and code detection equipment.

Learn MoreINTELLECT+ integrated modular future-proof package inspection interface.

Learn MoreFILTEC 3-XR and 3-G x-ray, optical, and gamma fill level inspection system

Learn MoreAuraTec pressure detection with multi-point laser scanning technology.

Learn MoreOuter sidewall refers to the outside surface of a container, usually below the thread and above the base. This outer surface can often become visibly scuffed or chipped, especially in returnable glass or PET. While outer sidewall damages are unlikely to corrupt the product itself, external container flaws are the indications of low-quality standards most obvious to the end consumer.

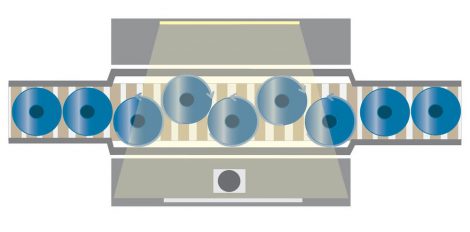

Twelve images are captured at 30-degree intervals while the bottles rotate past the inspection window,

providing the most thorough inspection and the fewest number of false rejects.

Bottles rotate against each other as they pass through the inspection field, allowing for 360-degree detection.

LED strobe passes high-intensity light through the empty containers to a high- speed digital camera where an image is captured and processed through a series of algorithms.

OmniVision3 all surface bottle inspection system.

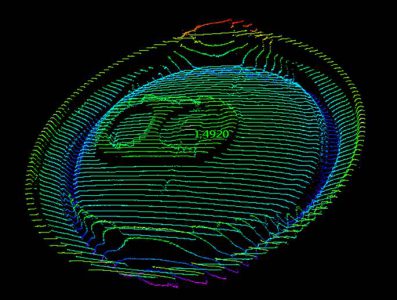

Learn MoreFaulty can pressure is often caused by dents, puncture holes, or improper seals. The AURAtec is a laser-based inspection system that distinguishes between low and high-pressure containers by assessing acceptable pressure profiles. The AURAtec functions with nearly a six sigma detection margin at speeds exceeding 1,200 containers per minute.

LaseTec4 high-speed laser coding, code verification, and code detection equipment.

Learn MoreINTELLECT+ integrated modular future-proof package inspection interface.

Learn MoreFILTEC 3-XR and 3-G x-ray, optical, and gamma fill level inspection system

Learn MoreAuraTec pressure detection with multi-point laser scanning technology.

Learn MoreVision modular vision system inspects fill level, closure, and labels.

Learn More