Many beer drinkers have joined the Craft Beer Movement….yes, it’s a movement. Drinking craft beer is an experience because there’s a different beer for any season and occasion. Craft beer manufacturers know that great beer makes for great times which is why they know the importance of quality. To ensure your beer maintains the integrity of your brand, conducting thorough bottle inspections is imperative. With today’s production line operating at high speeds, identifying defects requires a vision inspection system that can perform in any mechanical vibration working condition.

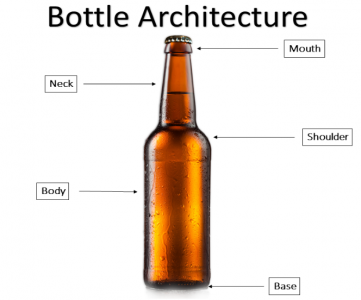

So, what are you really inspecting? First, you need to understand the architecture of a bottle. The bottle is divided into five detection areas: mouth, neck, bottle shoulder, body, and base. Each area of the bottle provides insight into what defects your vision inspection system should look for.

Because of the structure of the bottle and the washing process, foreign objects can easily adhere to the bottleneck and bottle body.

Because of the structure of the bottle and the washing process, foreign objects can easily adhere to the bottleneck and bottle body.- Detecting defects near the bottle mouth area involve fracture detection with accuracy and at high speeds.

- The shoulder area of the bottle can be somewhat of a challenge and detecting defects with accuracy can be tricky at higher speeds.

- You’d be surprised to what can linger in the base of the bottle. Can you believe cellophane can be present? Yes indeed it can and you want to be able to detect and remove that bottle from your production line.

To make sure you’re inspecting your bottle thoroughly, you need an EBI system that is fast, provides a full 360-degree comprehensive defect analysis, and easy changeover. Detecting defects with accuracy and speed will not only increase productivity and efficiency, your customers will appreciate the quality of your beer.

In summary, life is short, manufacture good beer that your customers will remember. Contact us to learn about our inspection systems for the craft brewer.